Lexicon

1. 1002- Large choice of extensions

The development of a slide (also called extension, displacement or translation) corresponds to the extension of the moving part in relation to the fixed part. It depends on the number of elements in the slide and is measured in relation to the folded length.

As standard, the slides offer extensions from 100 mm to 3,000 mm.

There are 3 categories of extension:

Partial extension ~ 0.7 L

Full extension ~ L

Super extension ~ 1.5 L

Partial extension: approximately 2/3 of the folded length, with part of the mobile element remaining inside the fixed element.

Full extension: approximately the entire folded length, with the intermediate element providing the additional extension.

Super extension: approximately 150% of the folded length, thanks to the product's two intermediate elements.

The development can be adapted to suit the conditions of use. This adaptation is based on the length of the ball guide. The extension can be reduced or increased by up to 10% of the standard extension. The extension influences the load capacity of the slide as well as the deflection: the greater the extension, the lower the permissible load.

Development is usually carried out on one side of the slide. However, in some applications, it may be necessary to access the drawer from either side of the fixed part. In this case, double extension slides are used.

Some products have no development and provide load support and translational guidance, such as linear guide rails.

2. 1001- Folded lengths

This is the length of the longest part of the guide.

For standard slides, stock lengths range from 150 mm to 2000 mm, depending on the part number.

It is essential to specify the part number AND the folded length to identify a slide.

The lengths held in stock correspond to current requests.

For standard telescopic slides, stock lengths range from 150 mm to 2,000 mm in 50 mm increments up to 900 mm, then in 100 mm increments from 1,000 mm.

Other lengths are available on request.

Please do not hesitate to contact us.

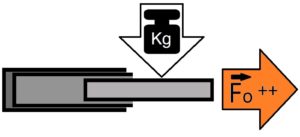

3. 1003-Load capacity

The load is the maximum effort which an extended pair of slides, mounted on the major axis, can bear. Load capacity varies from a few kilos to more than 1500 kg.

The maximum safe load is given:

- per a pair of edge-mounted slides,

- fully developed slides,

- uniformly distributed load on the small moving part of the slide.

4. 1004-Deflection

Deflection is the non permanent deformation when a fully extended slide is loaded.

This deflection is depending on to the extension, the load, the type of mounting (major or minor axis) and the mounting conditions. It is directly proportional to the load.

The figures are given on the product pages and on the technical data sheets.

5. 1005-Material

3 Types of materials:

- Steel,

- Aluminium,

- Stainless Steel.

STEEL

Chambrelan makes its slide profiles by cold drawing out or machining in long lengths, generally 6 meters. This manufacturing method improves the quality of the steel used due to work hardening. So, a cold drawn XC10 used in ranges like the RA5R offers the quality of semi hard steel on its ball tracks. On heavy-duty products, Chambrelan uses semi-hard type XC35 steels, also work hardened. The balls are made of chromium (100C6) steel.ALUMINIUM

Our profiles are mainly extruded 6060T5. The balls are made of chromium (100C6) steel.STAINLESS STEEL

Our stainless steel profiles are available in 304L or 316L, cold-drawn or rolled. The balls are made of stainless steel.6. 1006-Surface treatment

All slides are treated against corrosion.

Our standard treatment is zinc plating (RoHS compliant) for steel slides and colourless anodization for aluminium models suits most applications.

All slides come with a treatment against corrosion. The standard treatment, RoHS compliant, suits most uses.

7. 1007-Reinforced slides

Consist of enclosing reinforced ball bearings within the body of the slides.

This process restricts twisting of the beams under load and enables the load capacity to be greatly increased at the same time as it reduces the pull-out & push-in forces.

We mainly focus on heavy-duty slides. Among our products, we have developed a range of slides called “reinforced”, which has now replaced the standard slides.

This feature consists in the inclusion of additional reinforcing ball bearings within the body of the slides. This process reduces out the twisting of the beams when under load. This modification enables the load capacity to be greatly increased at the same time as it reduces the pull-out and push-in forces. The type of product is highly recommended for applications where the slide undergoes a torque or for mountings on the minor axis.

8. 1008-End stops

slides are fitted with stops which limit the extension, both for opening and closing.

Learn more

9. 1009-Locks

Optional locking devices enable the slide to be held in various positions: extended (V), closed (F) or both (VF). By manually activating the latch, the draw and slides are able to operate normally.

If considering the use of locks for vehicle applications, please contact us for further advice.

Three locking types are possible, i.e. :

Lock in the opened position

Lock in the closed position

Lock in the open and closed positions

The unlocking of the intermediate beam on 3 or beams slides is automatic. NB: In most uses, out of two slides, if only one is fitted with a lock, it is enough to block the drawer or the mobile part in the required position. The handle can be a useful device and provides easier access to lock systems.10. 1010-Double extension

An extension towards the front or the back of the fixed parts can be adapted on some slide types. Though easy to set up on 2 beams slides, it needs a synchronising system on the 3 beams slides.

Double extension is an extension towards the front or the back of the fixed part

NB:

- This makes the setting up of an internal locking system impossible.

- Flat mounting may be impossible on some slides; please refer to the product page for more information.

11. 1011-Table Slides

The outer beam includes 2 devices that extend on each side. This is suitable for example for tables with central opening.

12. 1012-Disconnect Option

Disconnection is an option on some types which allows you to remove the mobile part from the slide and then to insert it again in the same slide.

This option is necessary when installation is carried out in cramped premises where it would be hard to mount standard slides or for materials requiring maintenance.

This system is very technical and, therefore, very sensitive to mishandling. That is why Chambrelan prefers that fast hitching systems, such as studs, are used as often as possible.

13. 1013-Temperature

Standard operating temperatures are between -20°C and +80°C.

Some slides can be used within temperatures from - 50°C to +250°C.

Specific greasing can be applied. Please warn us before production.

Learn more...

14. 1014-Speed of use

Telescopic Slides

The maximum speed of use for telescopic slides is 0.3m/s.Linear rails

The maximum speed of use for linear rails is 0,5m/s.15. 1015-Items on stock

Our stock levels are constantly being topped up due to customer demands and a full ?real-time' stock program is available online.

For telescopic slides

usually in stock lengths range from 150mm to 900mm in steps of 50mm, then from 1000 to 2000mm in steps of 100mm.

For linear guides

For linear guides, length in stock are 500, 1000, 1500,2000 mm.

Products in stock are usually shipped within a few days.

If the reference is not available, we are able to produce slides, even for a few units.

We can sometimes change certain characteristics on models in stock, which reduces manufacturing time.

16. 1016-Manufacturing tolerances

Our production manufacturing tolerances are for cold drawn profiles, according to ISO 2768-cL.

Machining is compliant to ISO 2768-mK standard.

Our production manufacturing tolerances.

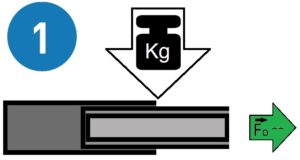

17. 1017-Mounting rules

Our slides are designed to be mounted on the major axis, per pair, with a uniformly distributed load on the smaller moving beam.

Some rules on good mounting:

Used by pair,

Mounted on the major axis,

Evenly distributed load,

Mounting surfaces are flat and even,

Use all fixings provided,

Slides are parallel on every axis,

Align slides fronts,

Use complete travel,

Distance between slides less than 2 metres,

Room temperature,

Fully extend slides before assembly.

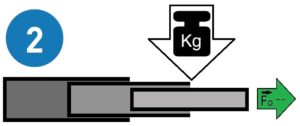

18. 1018-Mounting on a minor axis / Mounting with torque

Only some slides can be used for these types of stress.

A mounting on the minor axis reduces the load capacity of the slides.

Moreover, deflection and moving forces will increase.

Please refer to the product pages for more information.

Some slides need an increased space between the beams (ref C ) through spacers not supplied, in order to avoid the scraping due to the deflection.

19. 1019-Vertical mounting

For applications where a vertical "up and down" movement is required, we recommend our linear slides.

Due to vertical mounting, ball cages of telescopic slides will migrate after some cycles, which leads to a loss of extension.

We can limit this phenomenon with additional stampings.

Please contact us in case of vertical mounting before production.

20. 1020-Intensive use

In more demanding applications where shock and vibrations and excessive dirt are expected, we suggest nitruration of the beams.

Learn more...

21. 1021-Polluted environment

In harsher environments, where a build up of excessive dirt particles can lead to seizure, we recommend users regularly clean and maintain the slides.

You might also have to consider additional means of protection at the design stage.

22. 1022-Maintenance

To maximize worklife duration, slides are lubricated with a high pressure grease, which reduces the need for maintenance.

In more extreme working environments, slides need to be regularly and systematically cleaned.

Rails have to be regularly lubricated.

Learn more...

23. 1023-Options

The characteristics given on this website correspond to standard manufacture or usual requirements.

Our position as a manufacturer enables us to offer great flexibility in order to meet the most specific requirements.

So Chambrelan can easily adapt :

ExtensionsPart lengthsDrillings, diameters and hole centresSurface treatmentsOptions and fittings for fixingLubrication

Do not hesitate to contact us.

24. 1024-Modularity

As a manufacturer, we are able to offer numerous adaptations of products.

Our position as a manufacturer enables us to offer you numerous adaptations of our products. In addition, these products can also be mounted together to obtain new functions or specific sizes. Slides can thus be assembled with each other or with guidance rails, or even sometimes with ball bearing runners in the slides.

Do not hesitate to contact us.

25. 1025-Fitting

The various parts of the slides have manufacturing tolerances. The tolerances are offset by fitting different ball bearing diameters to ensure an easier movement. The standard fitting is suitable for most applications.

According to your needs, the slides can then be assembled very tightly, or, conversely, very loosely,if the application requires it, as is the case for mountings in hot enclosed spaces.

26. 1029-linear rails

Our linear rails consist of a recirculating ball bearing carrier that slides within a fixed length of guidance rail. One or more carriers may be used within each length of rail.

The linear guide rail is made from a 6 metres long cold drawn steel profile (some are in aluminium or in stainless steel).

This manufacturing method causes a strain hardening which gives the material the wear resistance qualities of half-hard steel.

The rails are fixed with screws. At the customer's request, the pitch as well as the number of holes can be adapted to the specific conditions of use.

Be careful:

Drilling is an option. Without a request from the customer, linear rails will be delivered without drilling.

27. 1030-Load capacity

The Load capacity quoted for each type of carrier is the maximum load for a single carrier.

The loads shown in the specification charts are given per runner. Although they are calculated with a large safety margin, the applied loads have to be considered according to the method of use or the orientation of mounting chosen for the application. So, an intensive use forces us to reduce the maximum load carried. Likewise, a mounting on the minor axis reduces the maximum safe load.

NB:

The loads usually carried by this type of product usually contain a high element of torque. So, you have to centre the load as much as possible, or use a second runner to cancel out this torque.

Please refer to the technical data sheet to view the exact figures.

28. 1031-Travel

The usual travel of the carrier is equal to the rail length minus carriers length and the stop measurement.

We supply up to 2 m rails in one part. The rails go together to allow longer travel length.

29. 1032-End stops

Our linear products are delivered with end stops: pin covered with rubber. They are designed as permanent end stops.

In case of additional end stops, it is important not to bump on the plastic part of the runner.

Accessories

End stop for transportation: Our linear products can also be delivered with transport end stops that are designed only to prevent the carrier from coming out of its rail. They should not be used as permanent end stops. It is very important to retain the runners with end stops. Indeed, if the runner should come out of its guidance rail, the balls, not being trapped would fall free and get mixed up. It would then be impossible to mount the runner again as we make up for the manufacturing tolerances by using slightly different ball diameters.30. 1034-Drilling

The carriers are predrilled and cannot be modified.

Standard rails are delivered undrilled.

Drilling patterns can be supplied at an additional cost and delivery times.

31. 1035-Mounting recommendations

Linear rails with recirculating ball bearing carriers are simple and robust products that will give you smooth and reliable travel.

Some mounting rules have to be fulfilled:

Mounting surfaces are to be flat and even,

Fix along whole length of rail,

No torque on runner,

Protect the rail from ingress of dirt,

Room temperature.

Temperature:

Should slides be used in high temp (>100°C) please inform us pre-production as manufacturing processes need to be changed.

32. 1037-New products & Evolutions

We are constantly seeking effective, efficient & innovative solutions.

Some scheduled changes to our products are planned, some will evolve and some be withdrawn.

Please note the following examples; for more accurate and updated information please refer to our web site.

Learn more

Do not hesitate to contact us..

Slide and Tilt:

it will provide an easy access to high located drawers. Learn more...Handle

In additions to the slides, we can provide a system of ergonomic handle including different locking possibilities.Designed to withstand the toughest users, it offers an easy to implement turnkey solution, and adapt to most of installations. Learn more...33. 1040-Nitruration

It is an optional heat treatment, which provides an increased surface hardness.

in the case of high use such as on a car production line, or, in case of fast movement (more than 0.3 meters per second), we advise this surface treatment.

This treatment gives the material a surface hardness of about 35 HRC, a hardness equivalent to that of the ball bearings'. Resistance to wear is, thus, greatly improved. Obtained under vacuum, it penetrates the material better than salt bath treatments. In this way increased hardness is effective to a depth of almost 3 tenths of a millimeter .

34. 1041-Method used to test loads for telescopic slides and linear rails

Loads are determined to ensure comfortable use, following a strict protocol of theoretical calculations validated by testing on bench.

We determine the acceptable standard load, according to our mounting conditions and standard use to provide proper operation: a soft and smooth sliding during an average lifetime.

The protocol follows the following steps:

With a computer calculation, the initial test load is determined by the tensile strength (Rm) and the yield point (Re).

This load is applied to the test frame to validate the calculated figures.

Once this calculation validated, we repeat these steps on other representative lengths of the range.

Eventually, a test on 15,000 cycles is performed on the most solicited length.

35. 1043-Synchronization of full extension or super extension slides

1- Purpose of this sequential device

2- Concept

3- Advantages of this mechanism

4- Limitations and contradictions

5- More information?

On some slide references, a sequential opening of the beams is possible.

On some slide references, a sequential opening of the beams is possible.

2- then the moving element can expand:

2- then the moving element can expand:

This system, which is possible on some heavy duty 3 or 4 beams slides, considerably reduces the opening forces by controlling the opening order of the telescopic slide beams.

It is achieved :

This system, which is possible on some heavy duty 3 or 4 beams slides, considerably reduces the opening forces by controlling the opening order of the telescopic slide beams.

It is achieved :

1- Purpose of this sequential device:

In a normal telescopic slide, the opening of the beams can be done in a nonsequential way. The moving beam extends first. The other elements of the slide are then subjected to a torque which increases the force required to move them out. On some slide references, a sequential opening of the beams is possible.

On some slide references, a sequential opening of the beams is possible.

2- Concept:

Synchronization (or sequential opening) solves this phenomenon: 1- the moving beam is kept closed until the intermediate is completely opened. It is therefore subjected to a reduced torque, whilst extended. 2- then the moving element can expand:

2- then the moving element can expand:

This system, which is possible on some heavy duty 3 or 4 beams slides, considerably reduces the opening forces by controlling the opening order of the telescopic slide beams.

It is achieved :

This system, which is possible on some heavy duty 3 or 4 beams slides, considerably reduces the opening forces by controlling the opening order of the telescopic slide beams.

It is achieved :

- either by magnetic end stop,

- or by mechanical levers.

3- Advantages of sequential opening:

- The opening force is reduced;

- The lifetime is increased;

- Ball cages migration due to insufficient parallelism is reduced.

4- Limitations and contradictions:

This system is not recommended in case of vertical use (guillotine). It also does not work in the case of high temperature installation (in an furnace).5- More information?

For additional information, do not hesitate to contact us... Few examples of sequential telescopic slides: RA7R E102036. 1044-Lubricating

Standard slides are delivered lightly greased.

We use a high pressure bearing grease for steel slides and a white grease for aluminum and stainless slides.

Learn more

Upon request, we can use:

food grease (compatible clean room)a high temperature greasea teflon free grease (for spray booths...)grease free mounting (although we do not advise this option)

The slides are delivered lightly greased. We recommend greasing abundantly raceways after installation, especially in case of intensive use.

NB:

Regular lubrication extends the life of slides.

37. 1045-Wiper

The slides do not have a device to protect against particles.

As with any ball bearings devices, telescopic slides and linear guides are very sensitive to projections of particles in the raceways. The balls bearing will be stopped by the obstable and sliding will be stopped.

We don't provide standard protection device against projections.Each case must be studied specifically. This should be considered at the design stage.

On some rails, we can provide an optional wiper.

E53

ST53

SNT

38. 1046-RoHS / REACh

All our standard products are compatible to the standards of health and safety currently in force.

To date, our products and production methods do not contain or use of substances subject to REACH and RoHS regulations.

39. 1047-ISO9001

Chambrelan is certified ISO9001:2000 for nearly 10 years.Our first certification was confirmed by Veritas on June 20, 2005.

It has since been regularly renewed.Our quality system is updated to be consistent with our production.You can download our certificate by following the link.